Index:

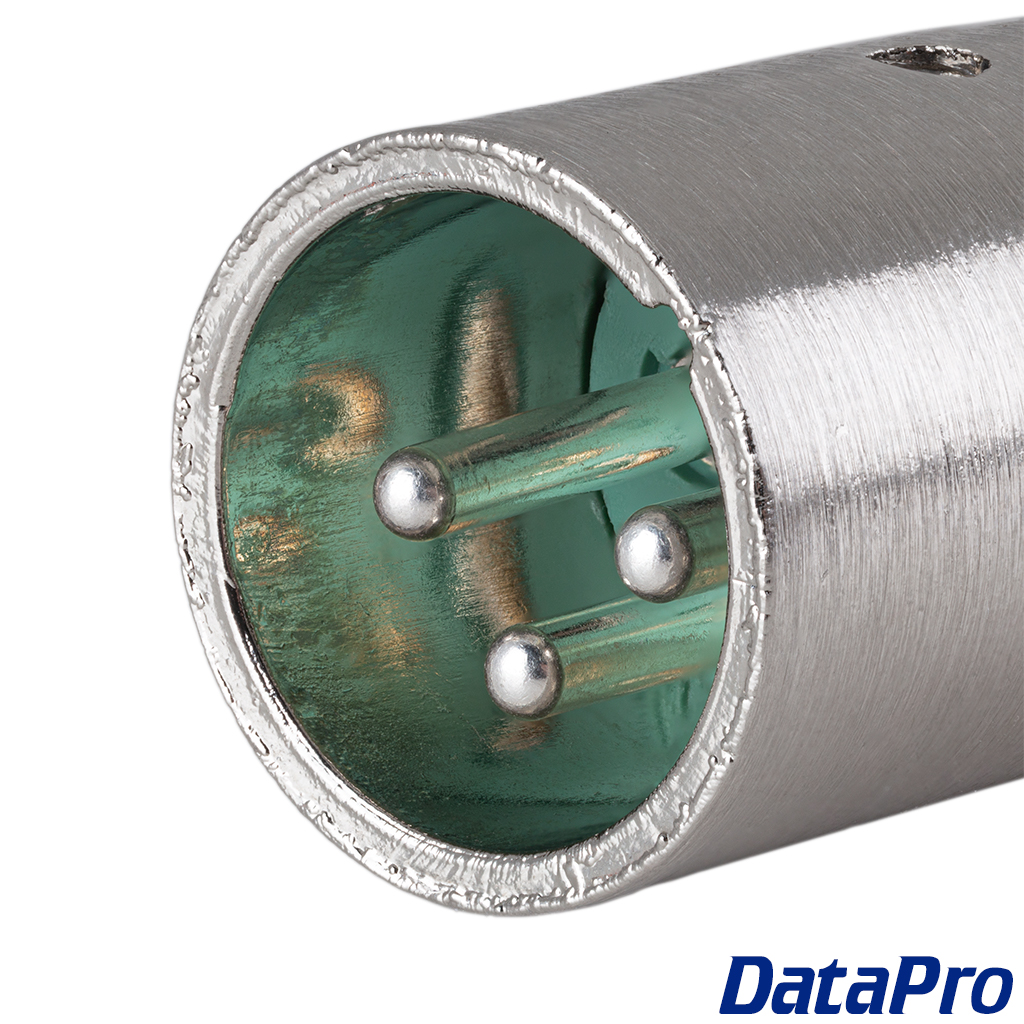

Nickel Plated Contacts:

Silver Plated Contacts:

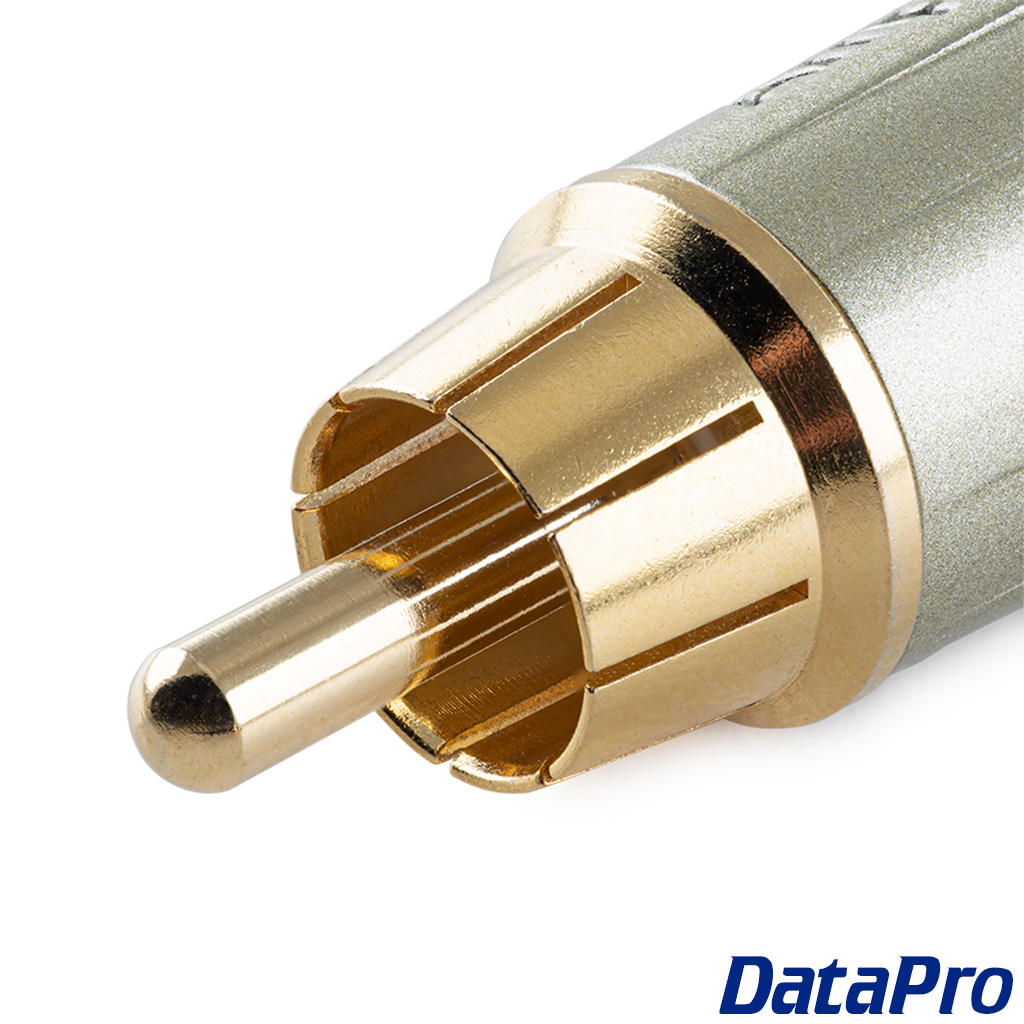

Gold Plated Contacts:

FAQ:

Advantages of Nickel-Plated Contacts

Cost-Effectiveness

While Nickel is not as conductive as gold or silver, Nickel-plated contacts are a much cheaper alternative if budget is a priority.High Corrosion Resistance

Before electroplating became more practical for manufacturers, most connectors used brass contacts which were corrosive. When technological advances made electroplating more feasible, nickel became the most popular choice because it is corrosion-resistant.Wear Resistance

Nickel-plating can help prevent wear on high-use components by reducing friction.

Disadvantages of Nickel-Plated Contacts

Lower Conductivity

Nickel's primary drawback is that while it's cheap and corrosion-resistant, it has poor conductivity when compared to other options. At 25% the conductivity of copper, mating connections will have slight electrical resistances, resulting in mild signal loss in the connection.Solderability and Weldability

Nickel can form a thin layer of nickel-oxide that must be removed before it can be soldered or welded.

- Panel Mount 3.5mm Stereo Extension Cable

- Dual Panel-Mount 3.5mm Stereo Cable F/F

- Stereo Cable 3.5mm M/M

- 1/4-inch Stereo Panel-Mount Extension

- 1/4-inch Stereo Dual Panel-Mount

Advantages of Silver-Plated Contacts

High Conductivity

The main advantage of silver-plated contacts is conductivity. Silver is 6% more conductive than copper and is the only pure metal that is more conductive than copper.

Disadvantages of Silver-Plated Contacts

Low Corrosion Resistance

Silver plated contacts are subject to corrosion if operating in unfavorable weather conditions. If This connector will be in use primarily outdoors, silver is probably not your best option. Silver is also a more expensive choice than nickel.

Advantages of Gold-Plated Contacts

High Corrosion Resistance

Gold-plated contacts, like nickel-plated contacts, are not subject to the corrosion that brass contacts and silver-plated contacts suffer from. For humid or otherwise harsh environments, this is a big advantage.

Conductivity

While not as conductive as silver, gold's conductivity is 73.4% that of copper which is much better than nickel.

Disadvantages of Gold-Plated Contacts

Cost

The main disadvantage of Gold Contacts is price. They are more expensive than nickel and silver-plated contacts, but if your connector will be facing the elements and you want to avoid the signal loss of nickel-plated contacts, gold is your best bet.

- XLR Panel-Mount Female Extension

- XLR Panel-Mount Male Extension

- Dual Panel Mount Neutrik XLR Cable F-F

- Panel Mount XLR Female 5-pin Extension Cable

- Panel Mount XLR Male 5-pin Extension Cable M-F

Frequently Asked Questions

Why Use Nickel Plated Connectors?

Nickel-plated contacts are used most commonly when corrosion resistance is a priority and price is a concern.Why Use Silver Plated Connectors?

Silver-plated contacts are used in certain situations where corrosion is not a concern and conductivity is of utmost importance.Why Use Gold Plated Connectors?

Gold-plated contacts are used in scenarios where corrosion resistance is a primary concern over cost.Is Gold Plating Better than Silver?

In most scenarios, gold is superior as a contact plating, due to its resistance to corrosion and relatively high conductivity. However silver's conductivity is even higher, which may be necessary for some applications.

Learn more about cabling and connectivity

Check out our comprehensive Tech Info page for a selection of informative articles!

Check out our comprehensive Tech Info page for a selection of informative articles!