DataPro offers two distinct types of surface labeling - Rotary Engraving, which involves the use of a CNC mill, and Laser Marking, which uses a high pulse fiber-based laser. Which one to choose depends on the job - read on to find out more.

DataPro offers two distinct types of surface labeling - Rotary Engraving, which involves the use of a CNC mill, and Laser Marking, which uses a high pulse fiber-based laser. Which one to choose depends on the job - read on to find out more.

Index:

Galleries

FAQ:

- What's the difference between laser marking, laser engraving, and laser etching?

- How do laser marking and engraving work?

- Does laser marking or engraving wear off?

- How deep can laser engraving go?

Rotary Engraving

As the name implies, rotary engraving is performed using a rotary tool - in this case a CNC mill. It works best with sans-serif fonts and medium-size lines.Rotary Engraving Pros:

- Won't fade

- Works on virtually any material

- Requires only a single manufacturing operation

Rotary Engraving Cons:

- Corners will all have a small curve equivalent to the radius of the engraving bit

- Fine lines must be cut slowly

- Large areas will often show a hatching pattern

- Requires coated or multi-layer material for best contrast

- Not ideal for small text

Materials:

- Aluminum:

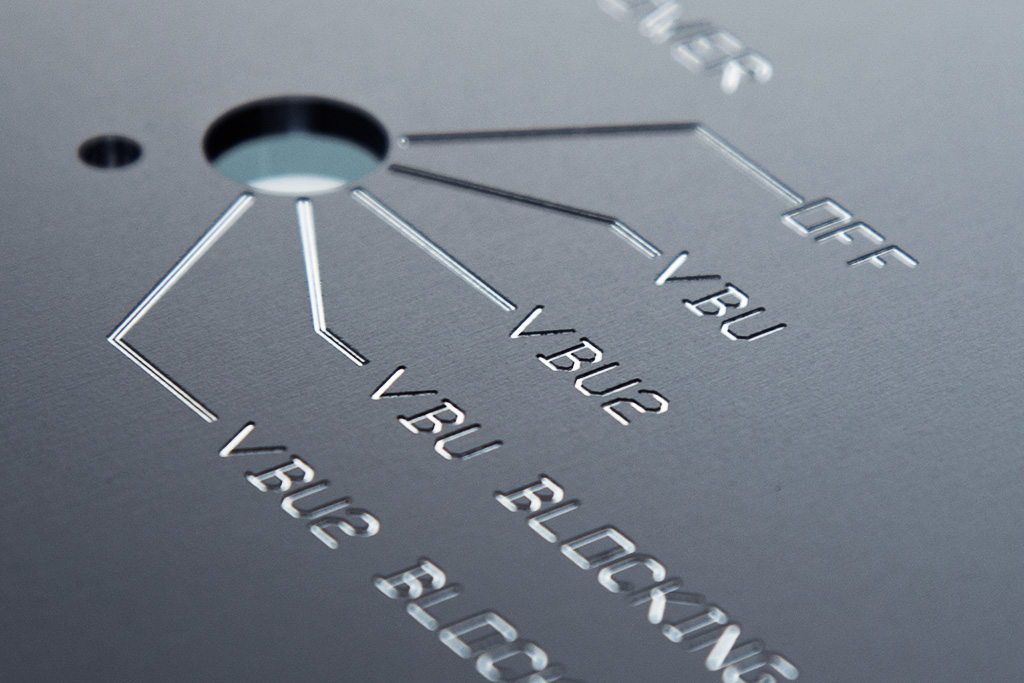

Rotary engraving reveals the shiny silver metal color under Dye Anodized aluminum, creating excellent contrast. Uncoated or clear anodized aluminum will typically result in a low-contrast mark unless a surface coating such as anodizing or paint is used.

- Acrylics:

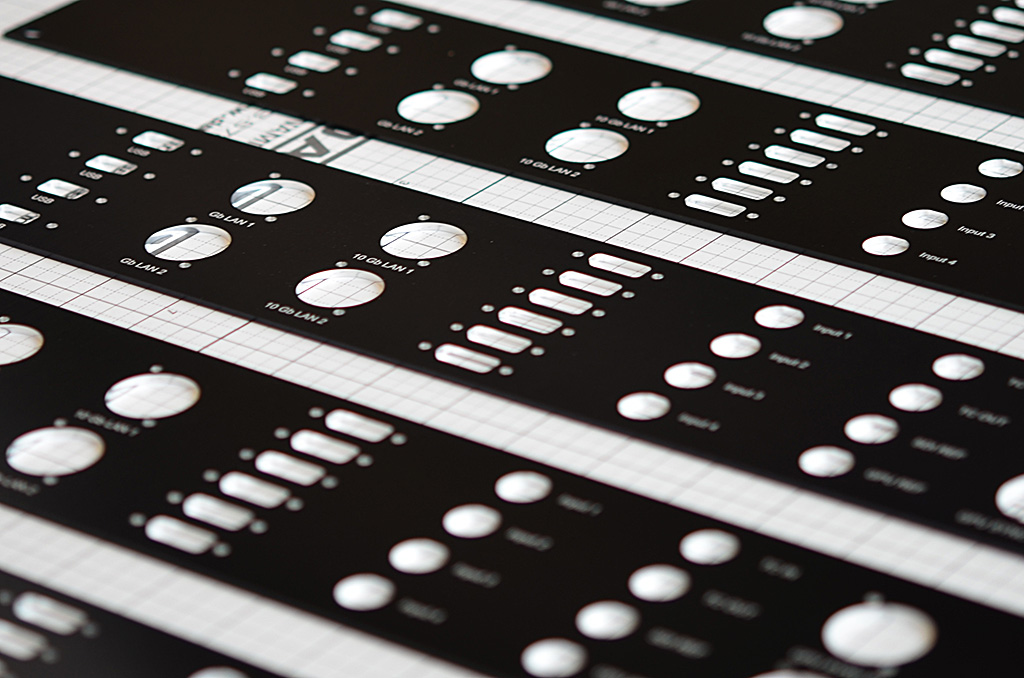

For contrast, we recommend acrylic laminates. These materials are specially manufactured in layers, allowing the surface to be milled or laser ablated away, revealing a contrasting color beneath. Standard acrylic can also be used, though markings may have low contrast.

Laser Engraving

Laser engraving works by either ablating the surface away, vaporizing its top layers; or heating the surface such that it changes the color.Laser Engraving Pros:

- Sharp corners and fine lines

- Quick marking time

- Large areas can be hatched without an obvious pattern

- Works great with serif fonts, even at very small sizes

Laser Engraving Cons:

- Filling large areas can be less efficient than rotary engraving

- Requires a second operation after milling, increasing production time and cost

- Some limitations to material size

Materials:

- Dye Anodized Aluminum:

Anodized aluminum is the perfect surface for laser marking. Depending on the setting of the laser, it's possible to either bleach the anodizing dye into a high-contrast white, or ablate it away altogether, creating a durable physical mark.

- Clear anodized or raw aluminum:

Laser marking on uncolored aluminum can produce colors ranging from white to medium-gray. For higher-contrast marking we may recommend alternative methods.

- Dark colored, mostly opaque acrylic:

The surface of the material is heated until it changes color, usually to white or light gray.

- Transparent or light colored acrylics:

Only a white mark is possible, which would be low contrast on light (or white) acrylics. On transparent acrylic the mark will be translucent white and may be slightly raised.

Frequently Asked Questions:

What's the difference between laser marking, laser engraving, and laser etching?

The easiest way to think of the differences between marking, engraving, and etching is like this:- Marking alters the color of the material, while leaving the surface flat

- Engraving cuts into the material, leaving a recess

- Etching heats the surface of the material, and can actually create a raised mark

How do laser marking and engraving work?

- Laser Marking works by oxidizing, heating, or annealing the surface of a material with a low-power beam, changing its color without disrupting its structure.

- Laser Engraving uses a high-power beam to vaporize material, creating a cavity in the material surface.

- Laser Etching uses a medium-power beam to melt or foam the surface of the material, causing it to change and expand rather than vaporize.

Does laser marking or engraving wear off?

Laser marking tends to produce an extremely durable mark that isn't easily worn off. However if the surface will be under a great deal of wear, we would recommend engraving instead.How deep can laser engraving go?

When used on ideal materials such as graphite, laser engraving is possible to a depth of 0.125" (3.17mm). However most metals can be engraved to a depth of 0.020" (0.51mm).