We offer a wide array of options and materials, including custom aluminum and steel enclosures. Lead time for Custom Enclosures is typically 3-5 days. Complex designs, large batches, and some finishing options can require a little additional time. Our custom enclosures are perfect for use in prototyping electronics or protecting sensitive equipment in boats, vehicles, and more. Contact us about ruggedized and weatherproof ratings, including IP67 and NEMA. Design an enclosure fully from scratch, or customize an existing rack enclosure, expansion bay, or equipment box. Our enclosures are produced in-house by an experienced team of professional engineers and machinists.

- Professional engineering support available

- Fast quote turnaround

- No minimum quantities

- Rush production available

- Laser marking & engraving

- Rigorous QA and inspection

Related Services:

Gang Plates, Rack Panels, Pelican Case Panels and more can be created online using our Custom Plate Creator!

Looking for Custom Panels? We do those! Check out or comprehensive Custom Panels page here.

Rack Panels and Rackmount Enclosures can be customized or fabricated to spec.

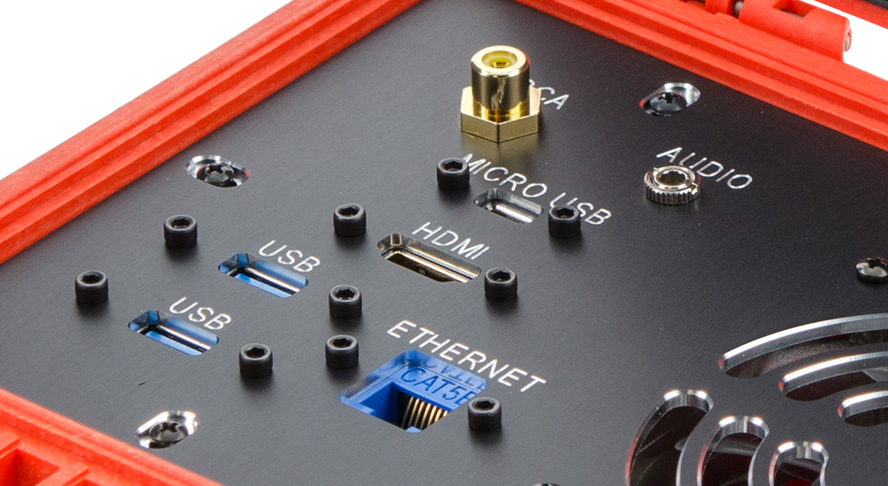

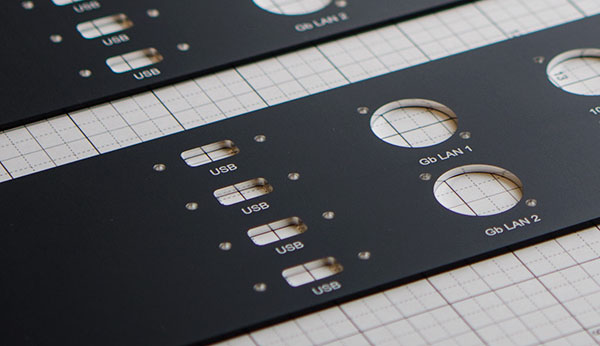

Gallery

Check out some of the finished products we've made for our customers!

Quoting

To request a quote, just email us your requirements. For the quickest and most accurate quoting, we'll need the following vital pieces of information about your project:

To request a quote, just email us your requirements. For the quickest and most accurate quoting, we'll need the following vital pieces of information about your project:

- Quantity

We have no minimum order quantity, but larger batches make for a lower per-unit price. Why not get some spares? - Manufacturing Method (more information)

Enclosures can be manufactured using one of three basic techniques:

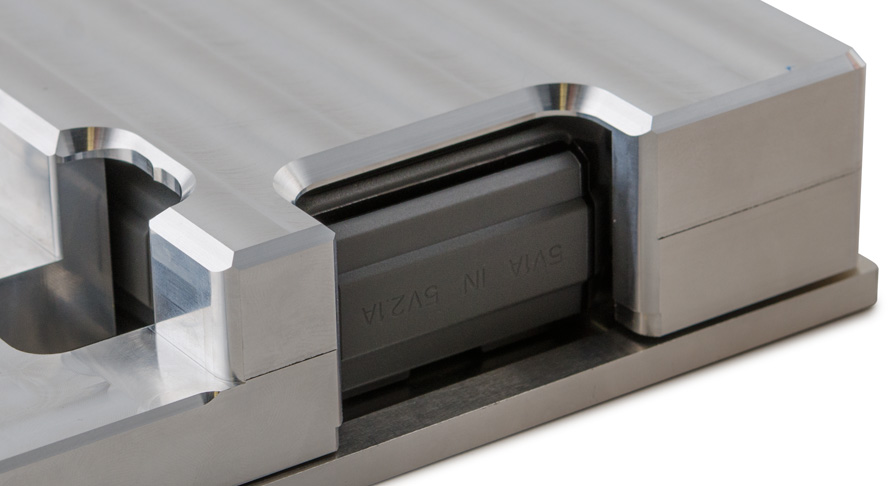

- Machined - The enclosure is hollowed out of a single piece of material.

- Metal Bending - The enclosure is milled out of a flat piece of metal, then bent into shape on a metal brake.

- Enclosure Modification - If you have an existing enclosure, we can customize it with cutouts, replacement panels, and more.

- Material (view options)

We stock a variety of popular materials and in multiple thicknesses and colors. If you have a specific requirement that isn't listed here, email us! - Anodizing (more information)

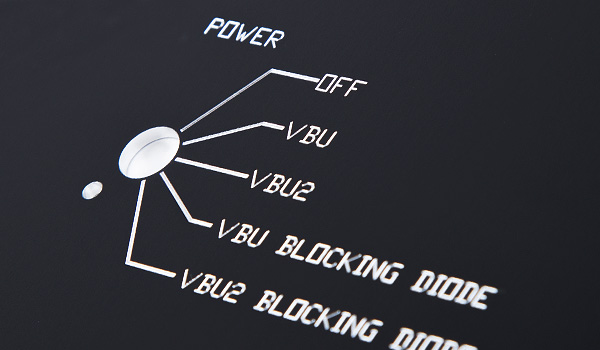

Enclosures cut from bare aluminum can be anodized after milling. This is most economical for orders of multiple enclosures, as it incurs a minimum batch charge. - Engraving and Laser Marking (more information)

If desired, indicate the type (engraving or laser) and placement on your drawing. If you have a preference for size or font, please include that as well. Otherwise we'll default to Helvetica and pick an appropriate size to fit. - Drawing

To give you the most accurate quote possible, we request that a drawing be submitted with your quote request. This drawing does not need to be to be overly technical, or to scale, but must include the following information:

-

Dimensions of the enclosure

Height, width, depth, etc. - Location of standard cutouts

Indicate roughly where you'd like your cutouts to be. If the location is specific, include its distance from two edges of the panel. - (Optional) Dimensions, clearances, and locations of nonstandard cutouts

If your panel includes any cutouts that are not on our list of standard cutouts, please include as much information about them as possible. We may also request a sample of the connector that will be installed in the cutout.

-

Dimensions of the enclosure

Manufacturing Method

CNC Subtractive Machining

With this method, the enclosure is hollowed out of a single piece of material.Metal Bending/Braking

Using this style, we first mill the flat outline of the enclosure, then bend it into shape.Enclosure Modification

We can add cutouts, accessories, internal structure, and other modifications to an existing enclosure.Available Options

DataPro offers a number of finishing and marking options, as well as accessories.

Marking & Labeling:

Laser Marking

For clean lines and maximum precision, laser marking is the perfect solution. Take a look at our Laser Marking Sample GalleryEngraving

This durable marking method looks great on any material with a contrasting surface treatment such as anodized aluminum or layered acrylic. For more information, see our Rotary vs Laser Engraving article.Finishing:

Anodizing

While pre-anodized aluminum is available, we can also anodize your panels post-cutting to provide a full-coverage durable finish.Accessories:

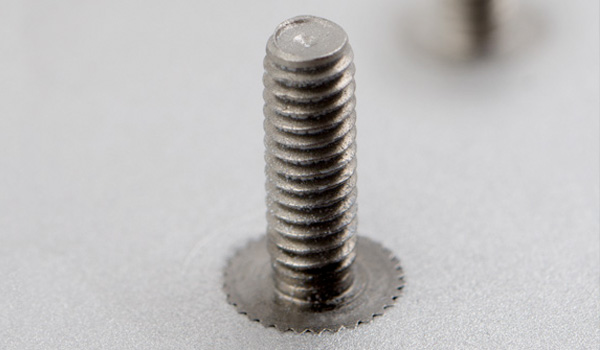

Press-Fit Fasteners

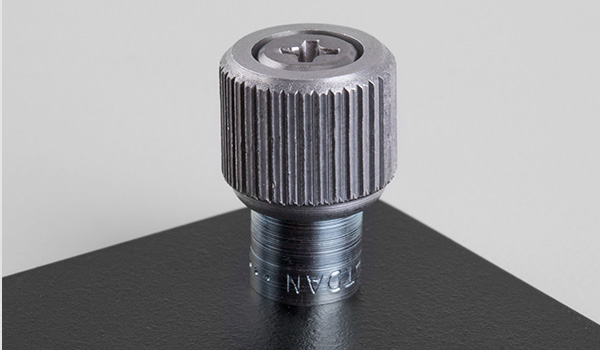

Mount PCBs, attach mounting hardware, and more with press-fit fasteners built into your panel. Concealed-head and flush-head available. Flush-mount nuts available on panels 0.090" and thicker. Perfect for adding windows and vents too!Captive Fasteners

Perfect for frequently-removed panels and components. These fasteners stay attached to the panel even when loosened, preventing loss or damage to equipment.Switch Guards & Hardware

We carry switch guards, panel handles, fasteners, and more. Check out our Accessories & Hardware section, or contact us if you have something specific in mind.Panel-Mount Connectors & Cables

Need to mount connectors on your enclosure? We carry a huge array of panel-mount cables, couplers, and connectors; all of which are guaranteed-compatible with the cutouts on your enclosure.Materials

We're happy to recommend the perfect material for your project. If you've got something specific in mind, we stock a variety of common materials in multiple colors and thicknesses, and can source nearly anything with a very short turnaround. If you don't see what you're looking for here, just contact us.

| 0.063" | 0.080" | 0.090" | 0.125" | |

|---|---|---|---|---|

| 5005 Aluminum Black Anodized |

• | • | • | |

| 5005 Aluminum Clear Anodized |

• | • | • | |

| 5005 Aluminum Raw/Unfinished |

• | |||

| 5052 Aluminum Raw/Unfinished - Contact us for anodizing and other finishing options |

• | • | • | |

| 6061 Aluminum Raw/Unfinished - Contact us for anodizing and other finishing options |

• | • | • | |

| Acrylic Matte or Glossy Black, 75% or 90% opaque White |

• | |||

| Layered Acrylic Black with White Core or White with Black Core |

• | |||

| Brass | • | • | • |

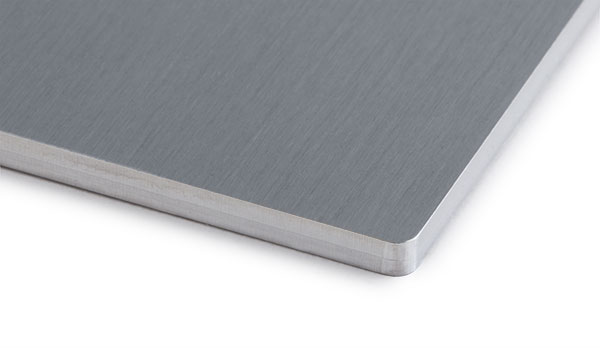

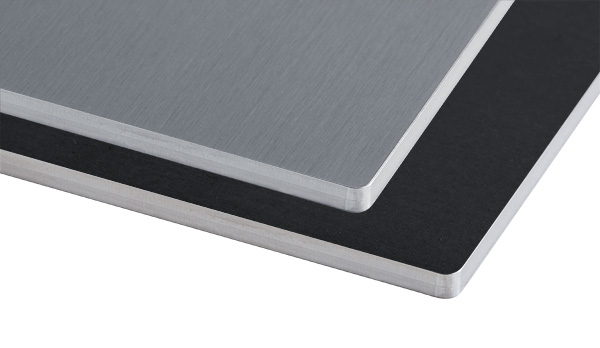

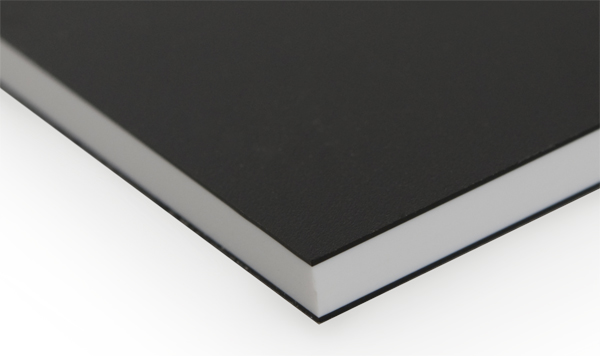

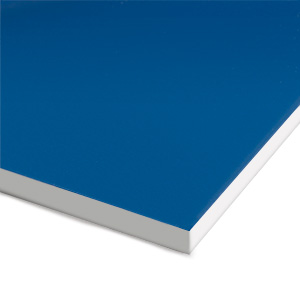

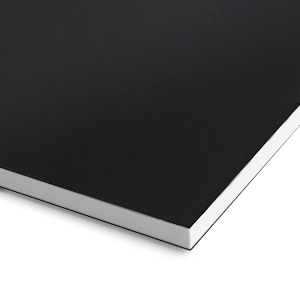

5005 Anodized Aluminum - Clear or Black

The material we use for our stock case panels. Anodizing is MIL-A-8625, Type II, Class 1 (Class 2 for Black).5052 Aluminum - Unfinished

This bendable, weldable alloy is perfect for enclosures. Stocked unfinished for post-cut anodizing or powder coating.6061 Aluminum - Unfinished

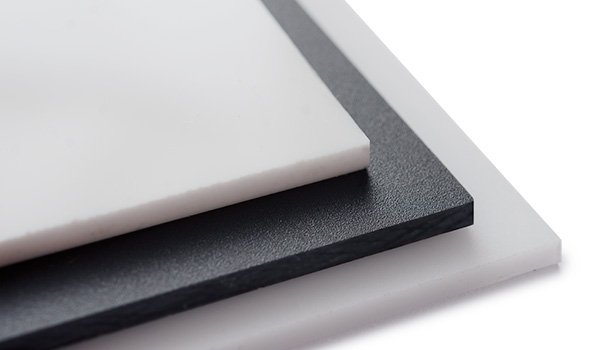

A popular and durable material that machines well and has high resistance to corrosion. While this high-strength aluminum isn't recommended for bending, it is heat-treatable and lightweight. Can be special ordered in MIL-A-8625, Type II, Class 1 (Class 2 for Black) anodizing.0.125" Acrylic

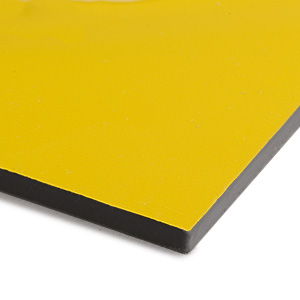

This acrylic material is lightweight and durable, with outstanding resistance to sunlight and weathering.0.125" Layered Engraving Acrylic

Made of three layers, with a contrasting color sandwiched between two shell layers. This makes for excellent, high-contrast direct engraving. Available in a variety of colors.

Standard Cutouts

DataPro's standard plate and panel cutouts are designed to be compatible with our panel-mount cables and couplers.

DataPro's standard plate and panel cutouts are designed to be compatible with our panel-mount cables and couplers.

Below you'll find a list of cutouts, their compatible components, and associated drawings. If you need something not listed here, please contact us!